Delivery documentation

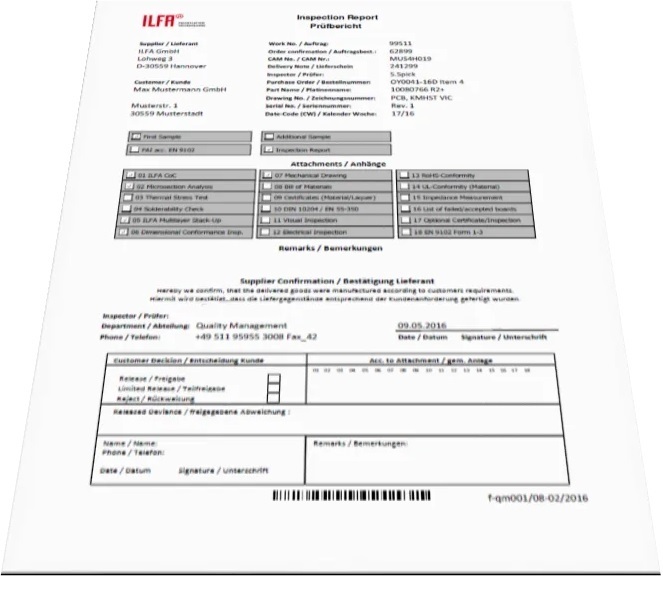

In addition to the current technological challenges that we as PCB manufacturers face in the production of your high-end PCBs, the requirements for delivery documentation have also grown steadily in recent years. The list of characteristics that we can document for you in a test report ranges from qualitative, attributive characteristics to quantitative, i.e. countable and measurable characteristics.

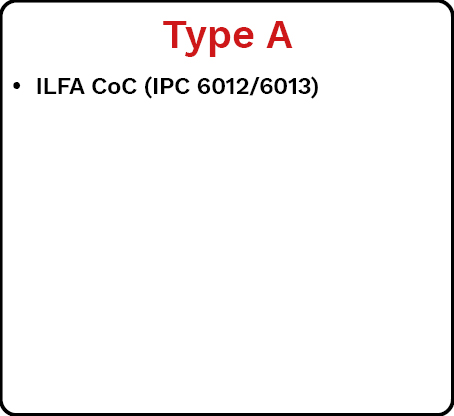

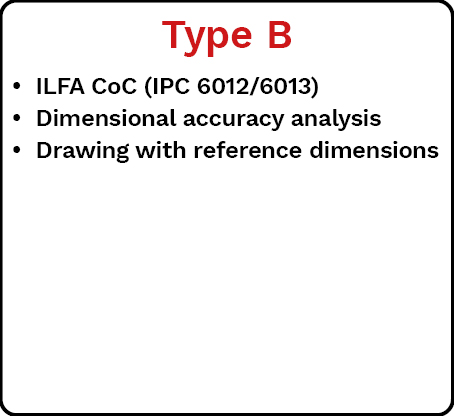

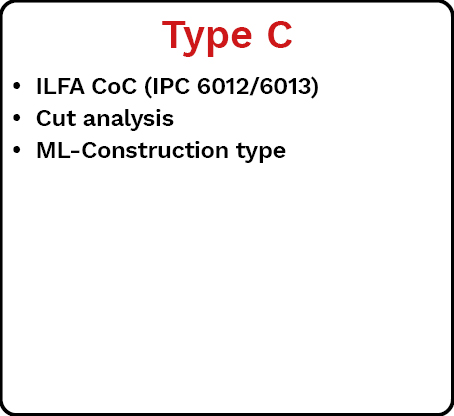

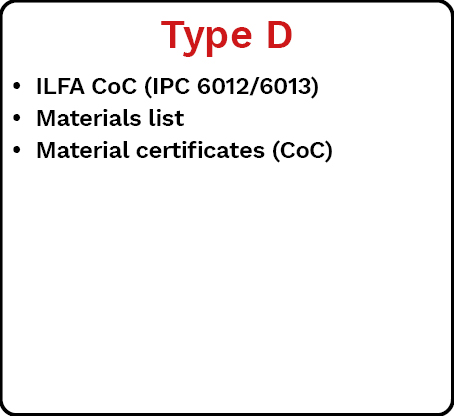

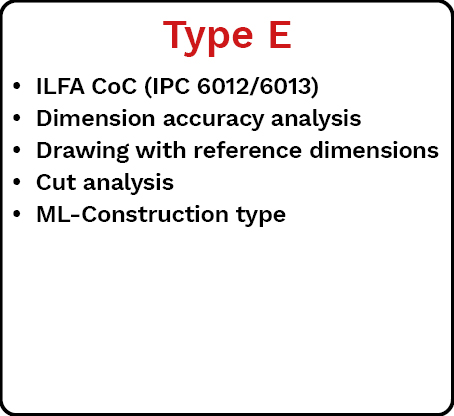

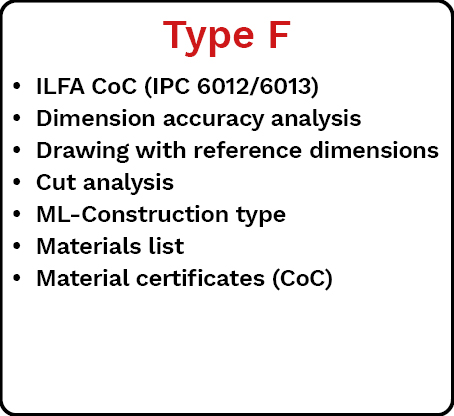

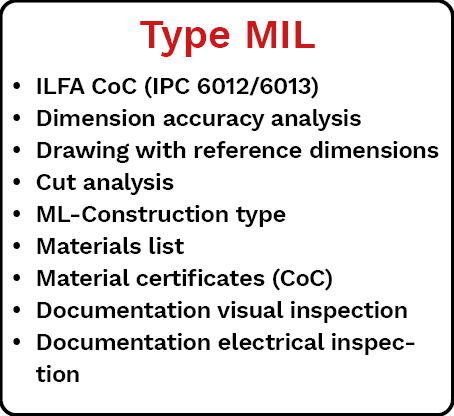

In order to make it easier for you to select the appropriate delivery documentation, we would like to provide you with some information here. You will learn which tests we can carry out for you and how we proceed with selected tests. At the end of the article you will find a table in which we have summarised different types of test reports as samples. Beyond that, many things are possible at ILFA. Let’s talk about it!

The need grows with the project

The individual scope of the test report depends largely on the specific requirements of your project. Properties that seem mundane and self-evident, such as the dimensions of the PCB or the layer thicknesses in the material composite of a multilayer PCB, can be decisive for the usability. We will be happy to record these special features for you in our delivery documentation.

The common pursuit of resource-conscious manufacturing may give rise to further documentation requirements. If your project requires it, we take into account conformity with statutory environmental protection directives such as REACH, RoHS and WEEE in the delivery documentation, as well as the current EU legislation regarding conflict minerals (EICC CFSI).

You have the choice

Here you will find our range of delivery documentation services from which you can choose. Contact us if you need additional information, our team will be happy to help you.