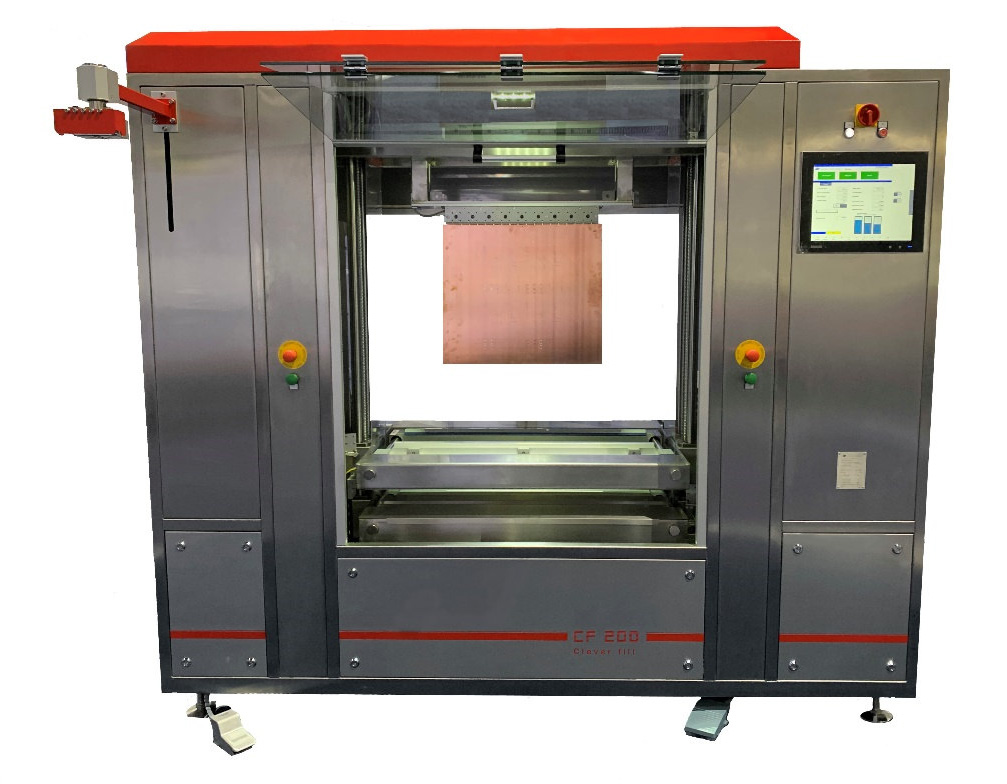

ILFA invests in new CF 200 high-vacuum plugging machine from I.T.C. Intercircuit

During the IPC APEX Expo 2024 in Anaheim, California, we awarded I.T.C. Intercircuit, one of the leading suppliers of equipment for the PCB industry, the contract for a new plugging machine. The CF 200 high-vacuum plugging machine is a real innovation: filling and cleaning take place in just one fully air-conditioned chamber, and through-holes and blind holes on both sides of the PCB are filled in a single operation. The new plugging machine saves us manual handling, as the doctoring process takes place automatically after filling. The paste fill level and consumption can be read in real time. Designed as a vertical single-chamber machine, it saves valuable floor space and the plugging machine is made entirely of stainless steel. It is conveniently operated via a Siemens PLC type S7-1500 control system, which is connected to a visualisation program on an industrial touch-screen PC.

With the latest generation of plugging machines, we are ideally positioned to fill blind holes and through-holes in complex PCBs in the future. We are reducing manual handling and at the same time optimising the consumption of the required plugging paste. The replacement of our previous plugging system will take place “on the fly”.

The CF 200 high-vacuum plugging machine from I.T.C. Intercircuit is part of our multi-million euro modernisation programme at the Hanover-Anderten site.