ILFA commissions RMV 125/6 lamination centre from LAUFFER

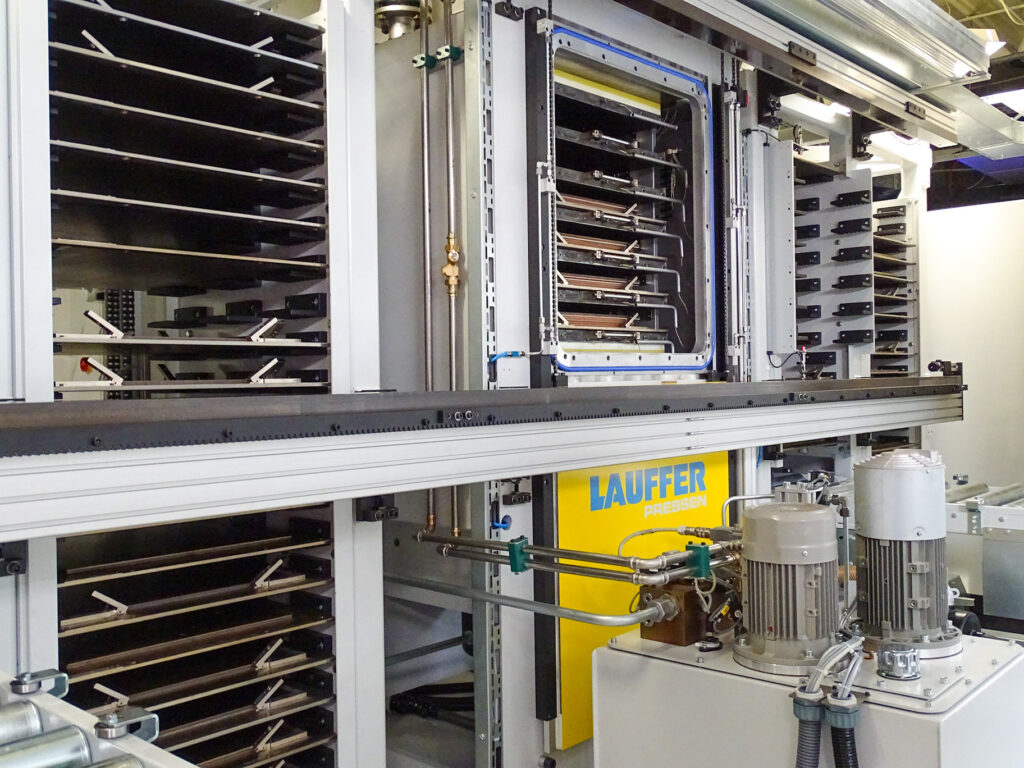

It is another important milestone in our modernisation offensive: with the commissioning of our new lamination centre from LAUFFER Pressen, we are tripling our lamination capacities in one fell swoop. The RMV 125/6 lamination centre forms the new heart of our multilayer department. The highly automated press has 2 heating and cooling presses, each with 6 levels for pressing high layer PCBs. Thanks to the unique design concept with large storage capacities, which has been specially adapted to ILFA’s requirements, the laminating system can also be operated fully automatically during night shifts or so-called ghost shifts. This also significantly increases the degree of automation within our PCB production at the Hanover site.

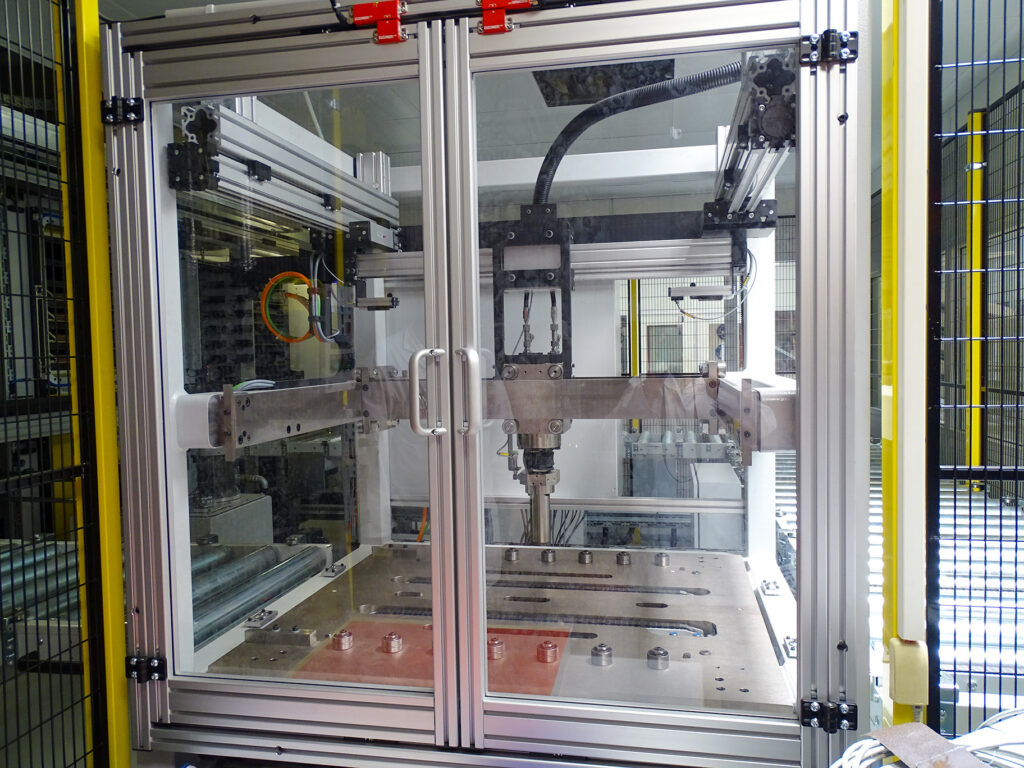

Two lay-up stations and a fully automatic destacking station as well as a loading and unloading store with 36 places each now ensure a high throughput in our multilayer department. A total of 72 tools are available and pressing can be carried out using both the Masslam and Pinlam processes.

With the installation of the new lamination centre, environmental protection is of course also taken into account, as the system is characterised by high energy efficiency during the pressing process. The newly designed heat accumulators for heat recovery during press operation enable energy savings of up to 30%.

It took around one year and 10 months from the needs analysis to the planning, through the project phase and finally to the installation of the press centre. The total investment amounted to around EUR 1.3 million. We would like to thank the LAUFFER team for their excellent work and exemplary support throughout the entire project.